Miscellaneous Studies

Simulated Annealing Algorithm

As discussed earlier, planarization during spincoating is an equilibrium problem in which the final film profile is determined when the net force in the system is zero. The explicit timestep algorithm currently used in our simulations does a satisfactory job of solving this problem; however, it is essentially a brute force method in which every timestep from the initial to the steady state conditions is simulated because of the interdependency between consecutive timesteps. From a modeling standpoint, only the steady state film profile is important, while the intermediate solutions only serve to slow down the simulation. The ideal solver would be able to eliminate some if not all of the intermediate steps required to achieve the steady state film profile.

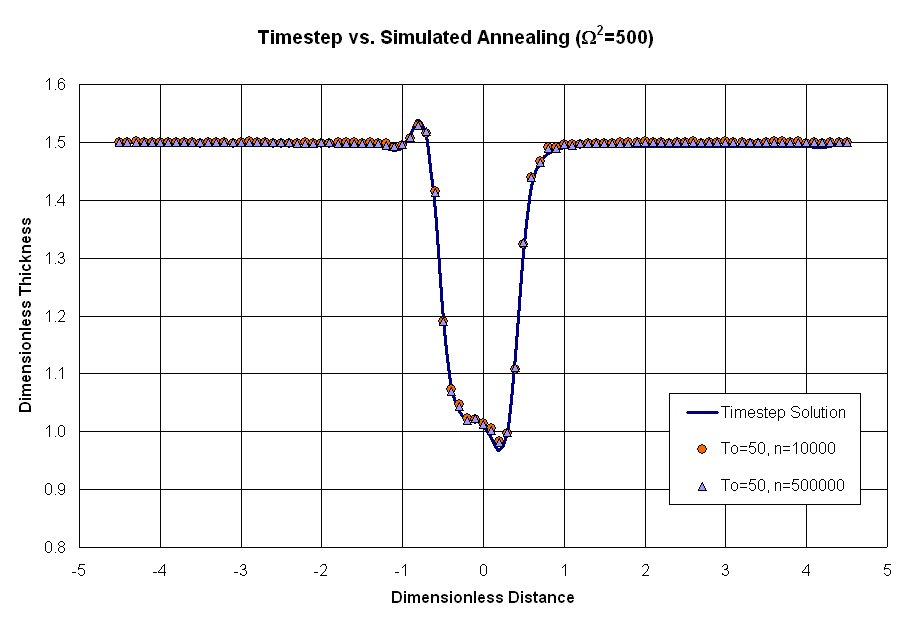

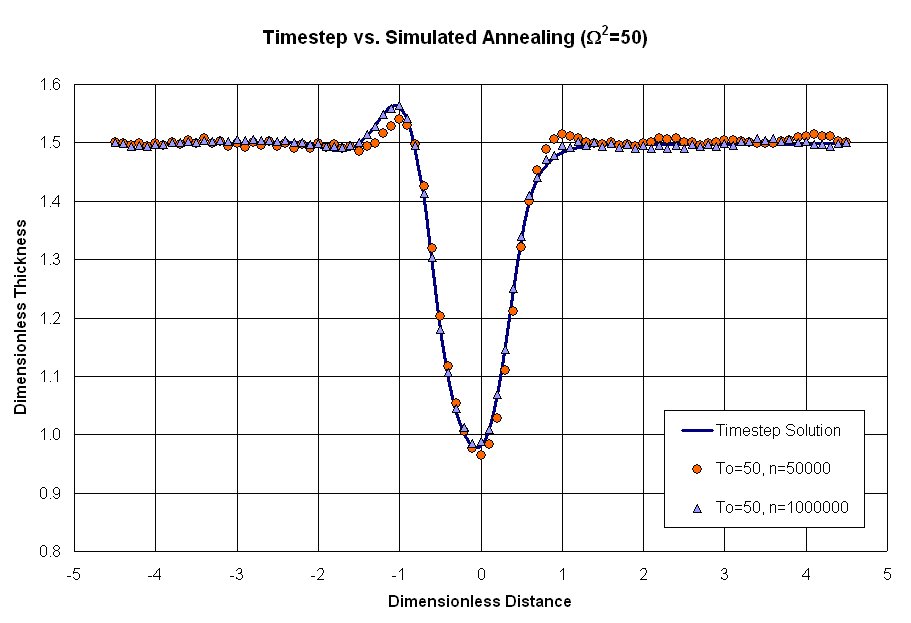

In this study, we employed a simulated annealing algorithm, which is a Monte Carlo method that locates the solution by minimizing the “energy” of the system. Simulated annealing can generate the steady state film profile up to 5X faster than the timestep method with minimal deviation in accuracy, which can prove to be advantageous if the simulation is used in a high volume manufacturing environment.

Figure 23. Comparison of film profiles using simulated annealing versus timestep at Ω2 =500

Figure 24. Comparison of film profiles using simulated annealing versus timestep at Ω2 =50

<--! Click here to download a movie showing a demonstration of the spincoating simulation using the simulated annealing algorithm (X MB). !-->Nonvolatile vs. Volatile Fluid Experiment

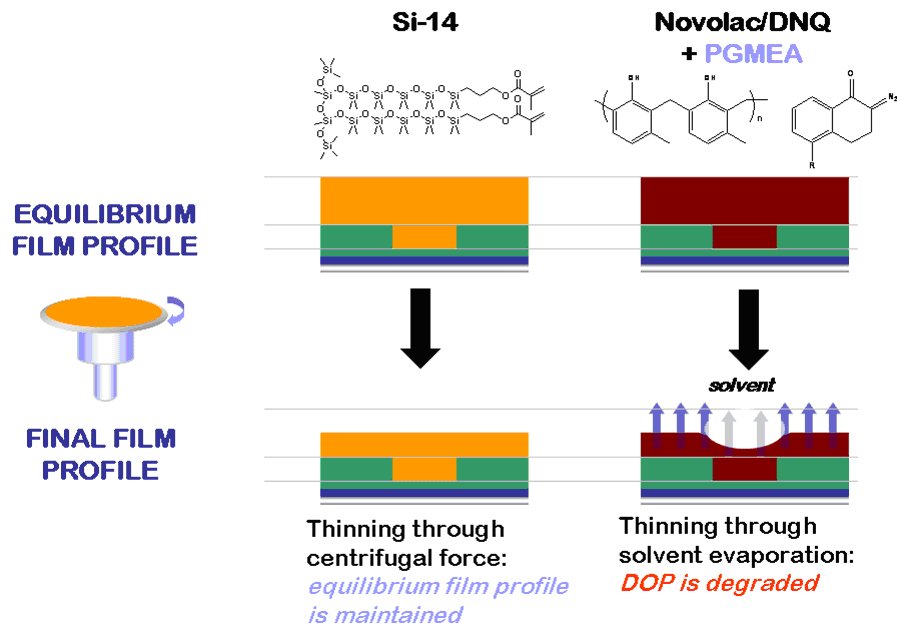

The purpose of the second experiment was to compare the planarization performance of Si-14 to a volatile fluid system during spincoating at various Ω2 values. The volatile fluid was a novolac/diazonaphthoquinone (DNQ) polymer system in PGMEA solvent.

Figure 25. Comparison of nonvolatile and volatile film thinning during the spincoating process.

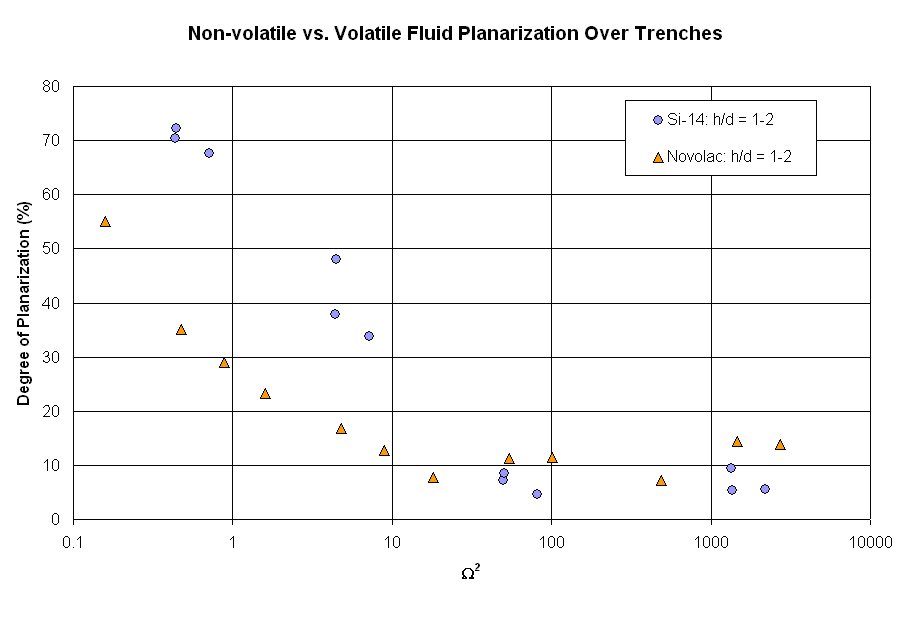

Figure 26. Si-14 and novolac/DNQ experimental data for planarization during spincoating over trenches

At small to intermediate Ω2 values, Si-14 does indeed have higher DOP values than the novolac/DNQ system, while at large Ω2 values, both samples planarize equally well. The data set for both fluids converge at Ω2 values greater than 100; however, it is important to remember that the Si-14 film can continue to planarize once the spinning stops, while the novolac/DNQ film will remain static.

Continue reading >> Support and Collaborations