Simulation and Design of Planarizing Materials for SFIL-R

Introduction

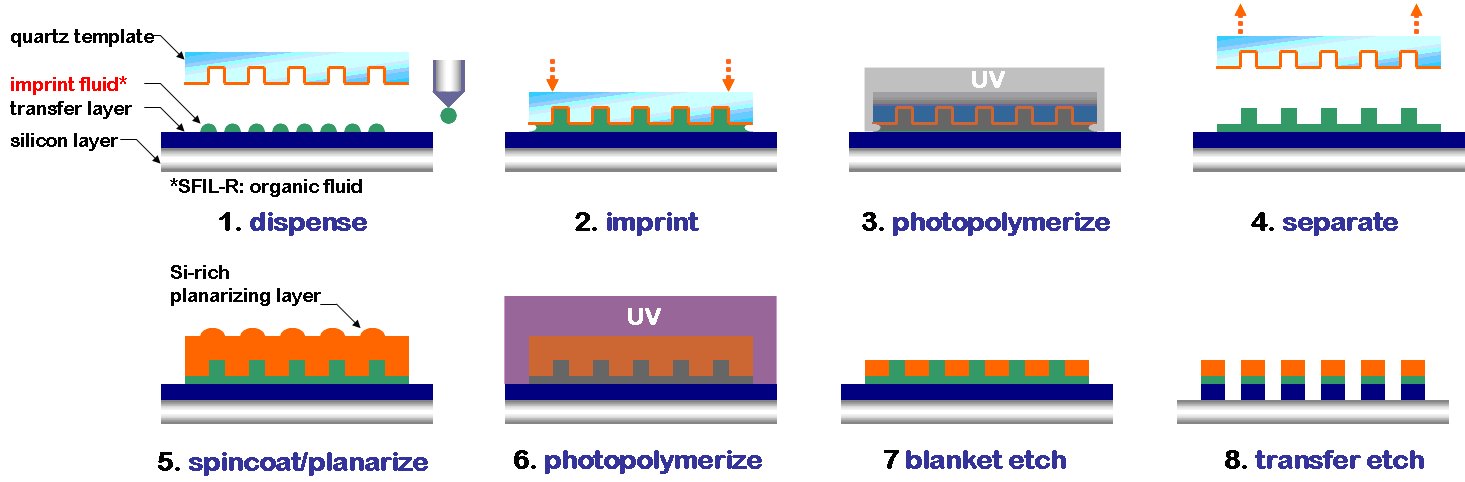

SFIL-R is a reverse-tone variant of SFIL that provides certain advantages such as higher selectivity during etch, superior in situ alignment, defect control, and throughput.

Figure 1: SFIL-R process flow

To reverse the tone of the image, the silicon-rich etch barrier used in SFIL is replaced by an organic fluid. Once the structure has been imprinted, a silicon-rich, photocurable film is applied over the patterned etch barrier. This topcoat serves as an etch mask providing high etch selectivity during the pattern transfer process, which allows thick residual layers to be etched without the negative effects of feature faceting.

The application of the silicon-rich topcoat is usually accomplished through traditional spincoating methods. During spincoating, surface forces coupled with the underlying topography can cause a conformal or semi-conformal film coating leading to the formation of a non-planar etch mask. As illustrated in Figure 2 subsequent etching of this non-planar film can lead to poor pattern transfer; therefore, there is a critical need to understand the forces governing the planarization process at the sub-micron level.

Figure 2. The flatness of the film affects the quality of the pattern transfer. A semi-conformal film (left) does not yield the desired pattern.

The goal of this project is to develop analytical and numerical models describing the planarization process and to use these models to aid in the design of novel planarizing materials for SFIL-R.

Continue Reading >> Theory