Experiments

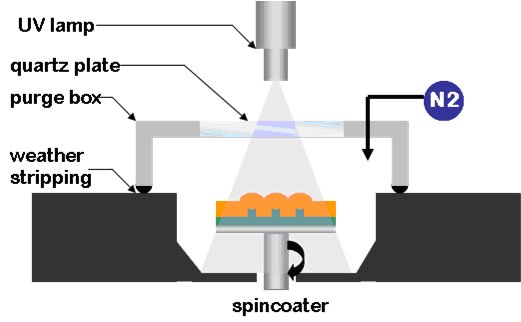

To validate the spincoating model, Si-14 was applied onto planarization test substrates at various spin speeds. Since the free-radical polymerization of Si-14 is oxygen-sensitive, a nitrogen purge box with a UV-transparent quartz cover was placed above the spincoater; nitrogen was introduced into the space prior to spinning, and the purge remained on through UV curing. A UV lamp (365 nm) was positioned above the purge box to provide UV curing during spincoating. To capture the equilibrium profile of the film during spincoating, the sample was irradiated while spinning, and the resulting film profile was measured using a profilometer.

Figure 16. Schematic of Si-14 spincoating experimental setup.

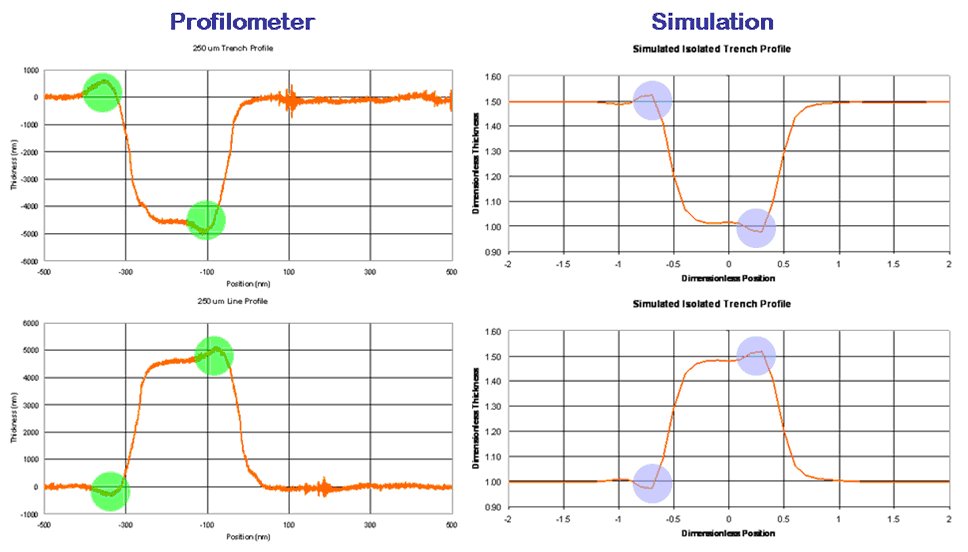

Figure 17. Profilometer traces and simulated profiles over 250 µm patterns.

The actual profiles agree well with simulation; ridges and dips detected by the profilometer are accurately predicted in the simulation. Experimental data was then compared to the simulation at various Ω2 and ho/d values

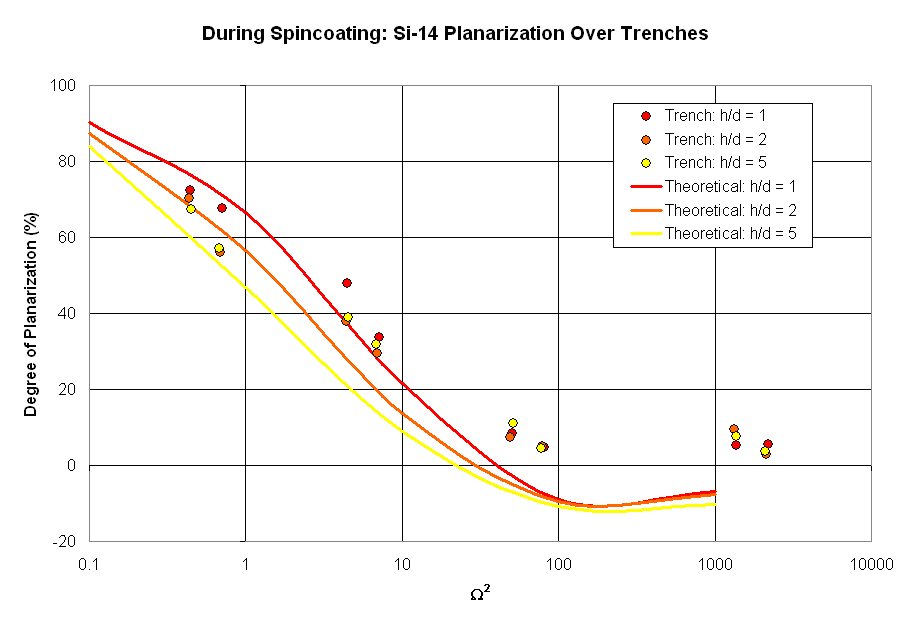

Figure 17. Si-14 experimental data with theoretical curves for planarization during spincoating over trenches.

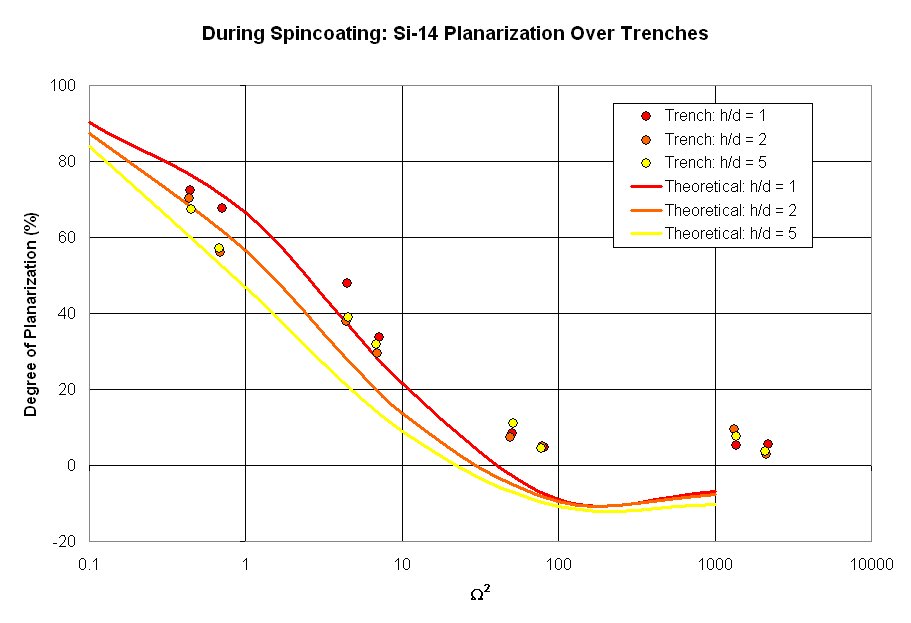

Figure 18. Si-14 experimental data with theoretical curves for planarization during spincoating over lines.

As illustrated in Figures 17 and 18, the experimental data agree well with the simulation curves for both trenches and lines.Post-Spincoat Leveling

To validate the post-spincoat leveling model, silicon oil and Si-14 were applied onto planarization test substrates under spincoating conditions that produced a conformal film at various ho/d values. The leveling of the fluids over isolated topography was then measured in real-time using interferometery.

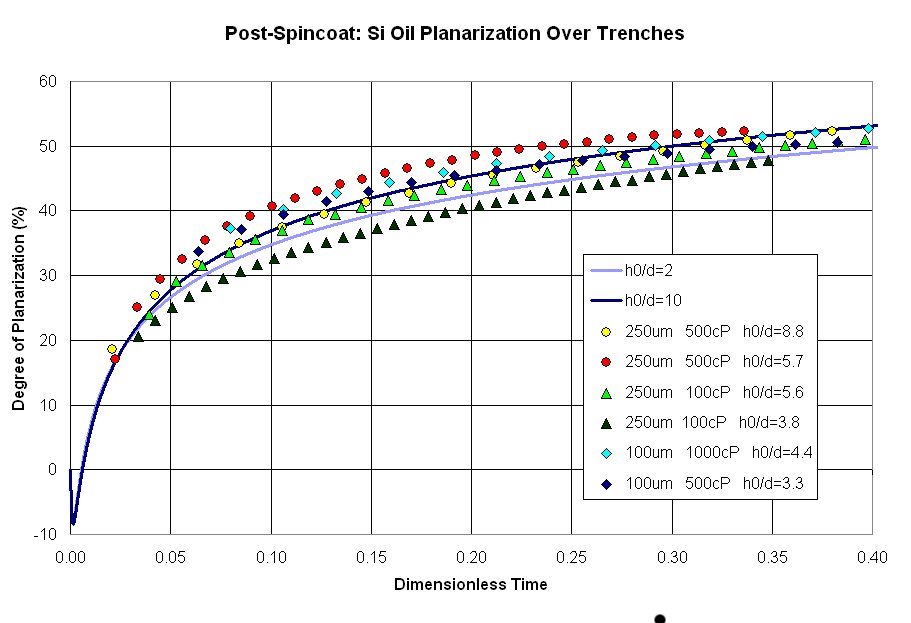

Figure 19. Silicon oil experimental data with theoretical curves for planarization after spincoating over trenches.

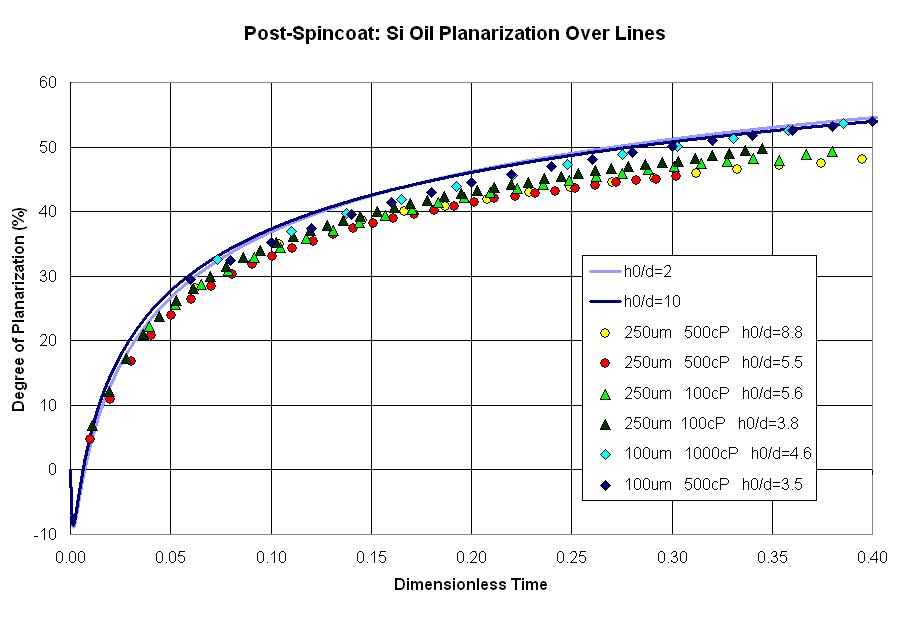

Figure 20. Silicon oil experimental data with theoretical curves for planarization after spincoating over lines.

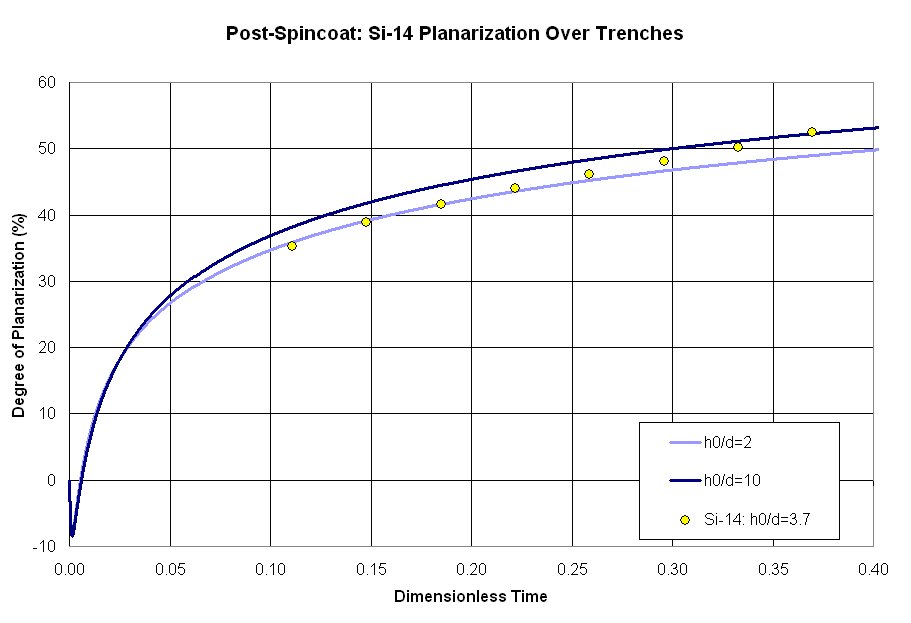

Figure 21. Si-14 experimental data with theoretical curves for planarization after spincoating over trenches.

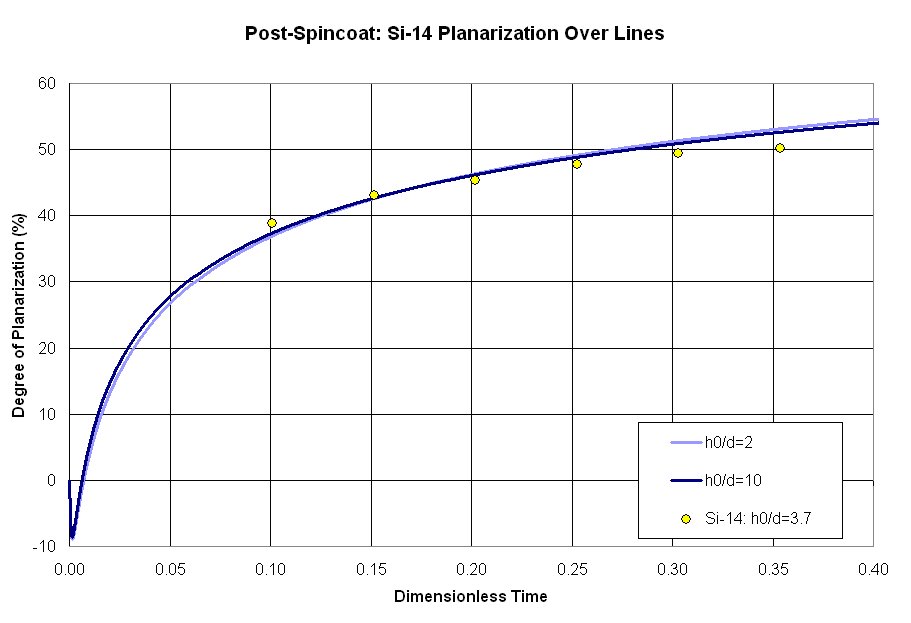

Figure 22. Si-14 experimental data with theoretical curves for planarization after spincoating over lines.

As illustrated in Figures 19-22, the experimental data fall on the simulated curves with minimal deviation. The results also show that lines and trenches do indeed planarize at approximately the same rate for large ho/d values. If the time is expressed in dimensional quantities, it is observed that Si-14 planarizes 250 µm features from 0 to 50% DOP in approximately 120 seconds.

Continue reading >> Miscellaneous Studies