Theoretical

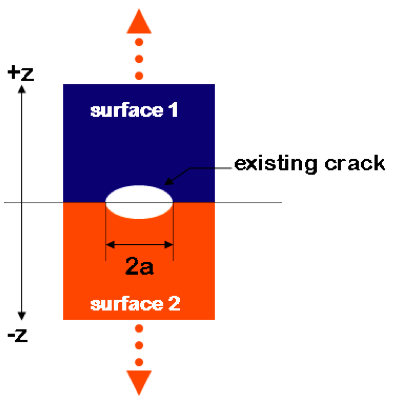

Figure 3. Diagram of crack propagation at a bi-material interface

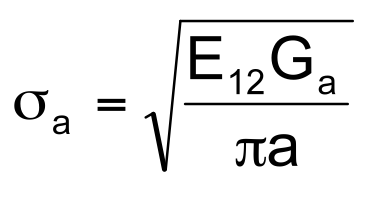

To design suitable materials and processes to reduce the separation force, it is necessary to determine the film and interfacial properties that affect the propagation of cracks by examining the mechanics of the SFIL separation process. The modified Griffith criterion for adhesion at a bi-material interface is shown below:

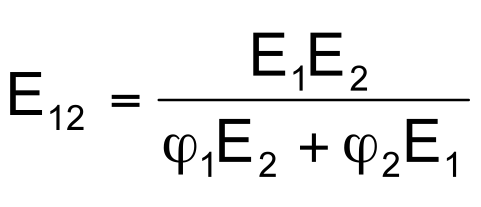

where σa is the adhesive fracture stress, Ga is the adhesive fracture energy, and E12 is a composite modulus given by

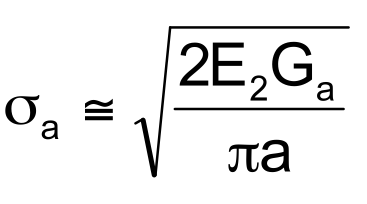

where Ei is the modulus of surface i and φi is the fractional length of surface i. Thus, the real adhesive strength is a function of the material properties, the loading conditions, and the presence and size of defects. For the SFIL process, quartz (surface 1) is in contact with a polymer (surface 2), which allows the following assumptions: E1 >> E2 and φ1 = φ2 = ½.

Therefore, in the SFIL process, the modulus of the polymer, the interfacial fracture energy, and the crack tip length at the template-polymer interface are the key parameters that control crack propagation.

Continue reading >> Experiments