Introduction

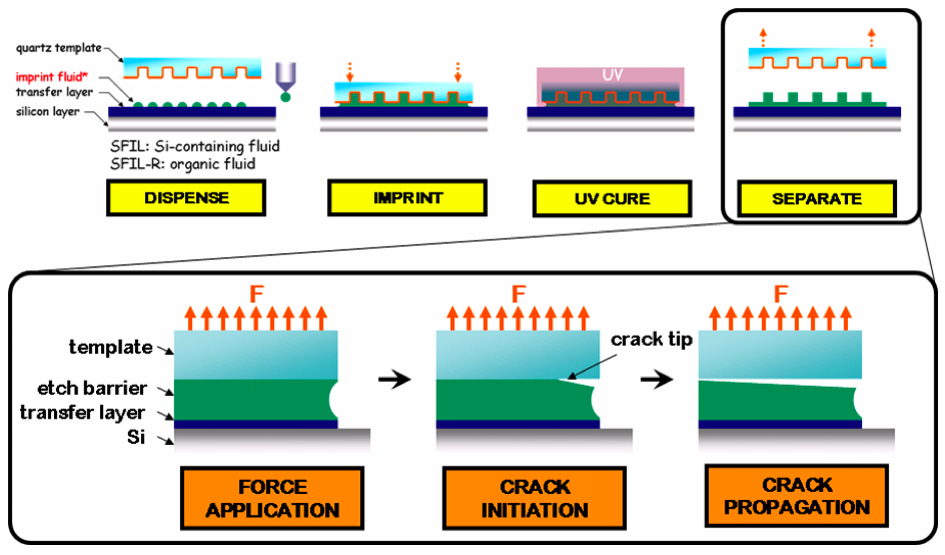

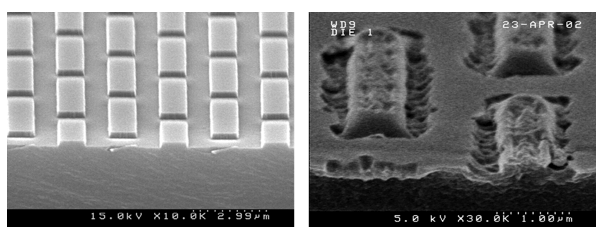

In the SFIL process, a successful imprint is dependent on perfect adhesive failure at the quartz-polymer interface when the template is removed from the imprint. Removal involves applying tensile forces on the template to propagate a crack along the often-complex topography of the quartz mold (Figure 1). If excessive force is required, cohesive failure of the polymer can occur and thereby generate defects on the polymer and quartz surfaces resulting in poor imprints and fouling of the template as shown in Figure 2.

Figure 1. Illustration of the SFIL separation process.

Figure 2. Cohesive failure of polymer (right) after template separation.

The problem is exacerbated if a silicon-containing resist is used. Cleaning the template without damaging the fine features can prove to be an expensive and time-consuming task since any reagent or process that attacks the silicon polymer will also attack the quartz template. The cost of SFIL templates are estimated to be about 1.5 times that of optical photomasks1, and throughput suffers whenever the template needs to be removed from the tool for cleaning. Therefore, there is a major push to develop SFIL-compatible templates and imprint materials that reduce the interfacial adhesion and subsequently minimize defect generation.

Continue reading >> Theory