Simulation

Feasibility Studies

We presented several materials that will potentially enable nonlinear dose behavior. These materials are not the only possibilities, but they do provide a reasonable range of resist designs to explore the feasibility of DEL as a technology choice. Of the proposed materials, only CELs and two-photon materials have been extensively studied and have established chemical systems. ISTP and OTL materials do not currently exist for use in semiconductor applications. However, their theoretical mechanisms are considered to test their viability as a possible DEL candidates. The materials represent a wide range of chemistries. To determine the best use of our resources, we first investigated the feasibility of the materials for use in DEL applications through simulation and used the results to guide our materials development effort.

Simulation Conditions

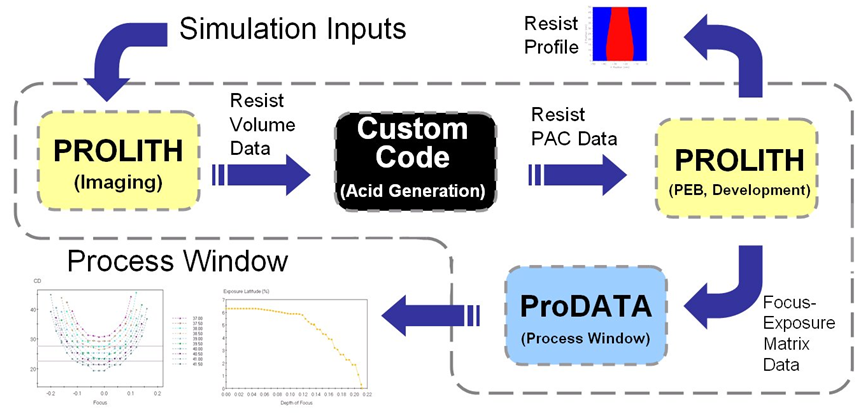

The performance of the different material types in double exposure mode and the dependence on their material properties were evaluated by computer simulation using a combination of PROLITH lithography simulator and custom code.

In all cases, the optical imaging portion was performed with PROLITH. The material responses of the reversible CEL was studied using the PROLITH simulator. However, commercial models for the ISTP and OTL materials do not yet exist as the materials are not currently used in production, so a custom simulator was developed to model the material behaviors in these systems.

Imaging Setup

A half pitch CD of 25 nm was targeted using a 1.2 NA water immersion exposure system in double exposure mode. This is an effective k1 of 0.155. An azimuthally polarized cross-quadrupole illuminator was used. Different masks were used for each of the two exposure passes. The masks were 50 nm line/space phase shift masks with 6 % attenuation. The two masks were offset by 50 nm between exposure passes. As described previously, DEL with positive tone resists is a trench-based process as opposed to the line-based process expected with a single exposure pass. Consequently, the target line is expected to form at the interface of the opaque and bright regions as opposed to the center of the bright regions. The film stack consisted of 50 nm of typical 193 nm resist on a layer of bottom anti-reflective coating. The substrate was silicon. In the case of the OTL and ISTP materials, the acid generation behavior differs from the base resist and was described with custom models.

Reversible Contrast Enhancement Layer (rCEL)

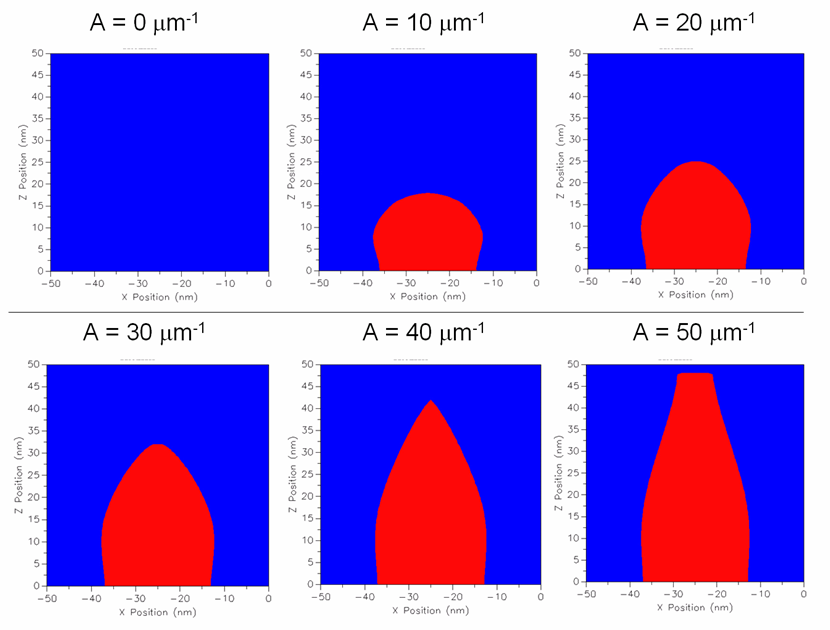

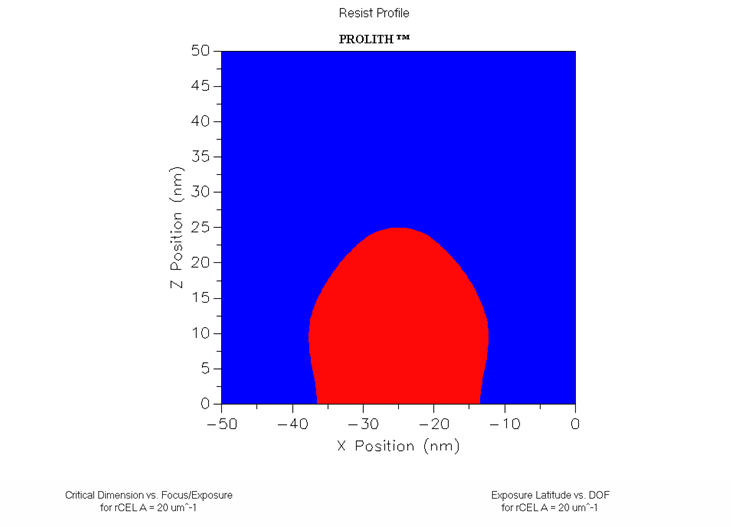

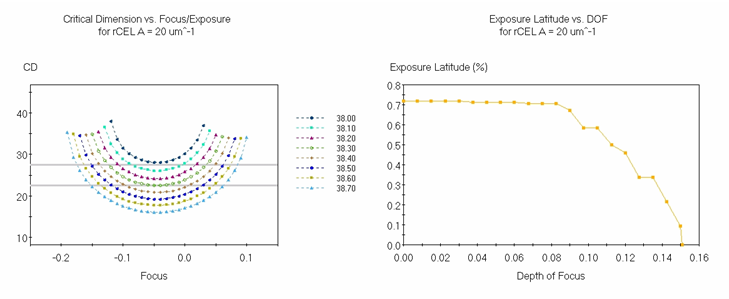

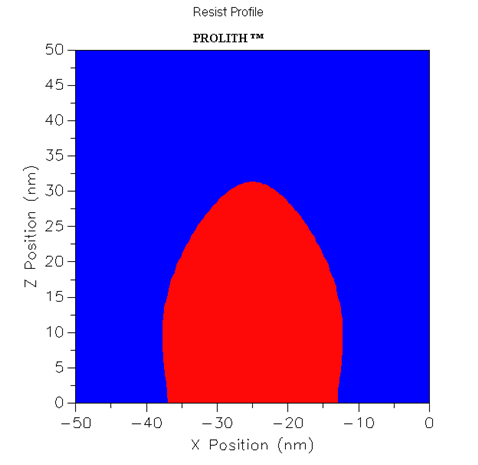

To study the CEL behavior, a 50 nm CEL was applied on top of the film stack. The Dill A parameter was varied from 10 μm-1 to 50 μm-1. Since a reversible CEL system provides better performance than an irreversible system, the rCEL was selected for the study. The resist profiles are shown below

The figure shows the effects of the Dill A parameter on the resist profile. For the test case of a Dill A parameter of 0 Μm-1, no resist profile was observed. This finding is consistent with the behavior of conventional resists since no nonlinearity was applied and further verified that the DEL process does not provide resolved images in conventional resists. In all cases, increasing the Dill A parameter decreased resist loss and improved the shape of the resulting image. The process windows are shown below

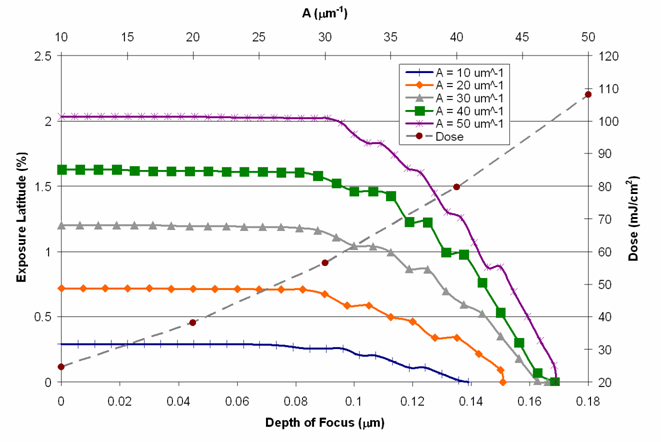

Increasing the Dill A parameter showed improvement for EL, but only marginal improvement was observed for the DOF. However, both improvements also led to increases in the dose requirement. An increase in the Dill A parameter from 10 μm-1 to 50 μm-1 required approximately 4.4 fold increase in dose. Another factor to consider is the feasibility of obtaining rCEL materials with high Dill A values. Without increasing the Dill A parameter, it is theoretically possible to increase the absorbance of the rCEL layer by increasing the layer thickness. However, the oblique incident angles resulting from operating at NA values greater than 1 may lead to loss in depth of focus if the layer becomes too thick.

The results for rCEL with Dill A parameter of 20 μm-1 has a comparable dose requirement to that of ISTP and OTL materials. Results from this run were used for subsequent comparisons with ISTP and OTL materials.

Intermediate State Two-Photon Material (ISTP)

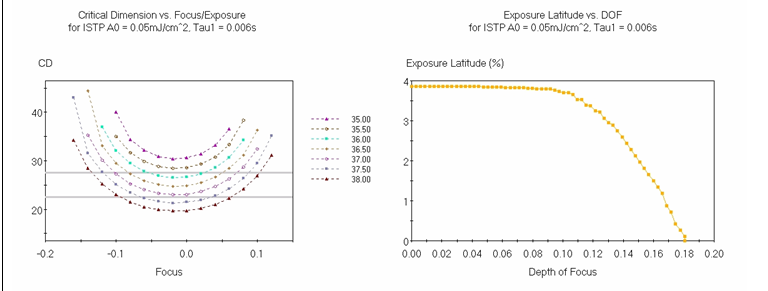

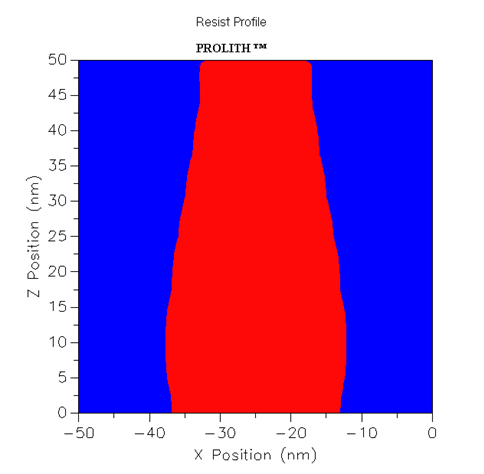

To study the performance of the ISTP material, the acid generation behavior was solved using a 4th order Runge-Kutta method. The resist profiles and process window are shown below

The ISTP resist profile is comparable to the rCEL results, but ISTP material has a larger process window than rCEL. The parameters of interest affecting the nonlinear acid generation behavior of the material are the energy delivered per pulse, A0, and the reversible rate constant of the intermediate state, τ1. For a given set of laser parameters, large values of A0 or τ1 lead to faster conversion of PAC thus reducing the required exposure dose. However, the dose reduction also leads to a decrease in nonlinearity. Since the laser can only deliver integer numbers of pulses, the magnitude of A0 has to be within a manageable increment such that small deviations in the pulse delivery will not drastically affect the CD. The parameters had to be optimized so that the system will retain nonlinear behavior but at the same time yield features within reasonable exposure dose ranges. ISTP materials showed a larger process window and improved resist profile than rCEL, and could be a potential DEL material provided that materials with the specified kinetics and time constants can be identified.

Optical Threshold Layer Material (OTL)

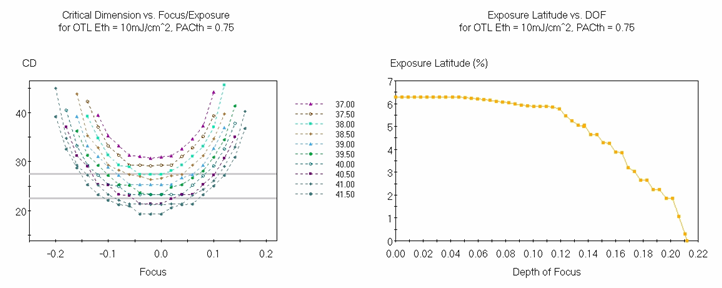

A dose threshold, Eth, of 10 mJ/cm2 was used with a threshold photoacid compound conversion, [PAC]th, value of 0.75. The resist profiles and process window are shown below

The profile shows a significant reduction in resist loss compared to both rCEL and ISTP resist profiles and slight improvement in the sidewall angle. The OTL material also has the largest process window of the three materials investigated. The threshold dose requirement behavior of the OTL material served effectively to filter out regions of low intensity. In addition, the threshold conversion response of the PAC resulted in improved image contrast. Because no such physical systems exist, the threshold dose, Eth, and PAC conversion, [PAC]th, were chosen such that they would provide a defined solubility switch within comparable dose ranges. Performance in physical systems may differ depending on the thresholding mechanism. OTL materials showed the best performance (i.e. largest process window and best resist profile) compared to rCEL and ISTP materials and would be suitable for DEL applications. This suggests that potential mechanisms, either chemical or physical, need to be explored.

rCEL materials demonstrated nonlinear behavior in DEL mode, however, image quality and process window improvement was only observed for rCELs with very high Dill A parameters. ISTP materials showed a larger process window than rCEL. The challenges with this approach are identifying materials with the specified kinetics and the ability to tune the time constants. OTL materials showed the best performance with the largest process window and best resist profile. There are no physically functional optical analogs with the thresholding behavior. Potential mechanisms, either chemical or physical, need to be explored. From our feasibility studies, we believe that the ISTP and OTL materials have the greatest potential for use in DEL applications and warrant our investment in materials development.

Continue reading >> Optical Threshold Layer