SFIL Filling Dynamics

Introduction

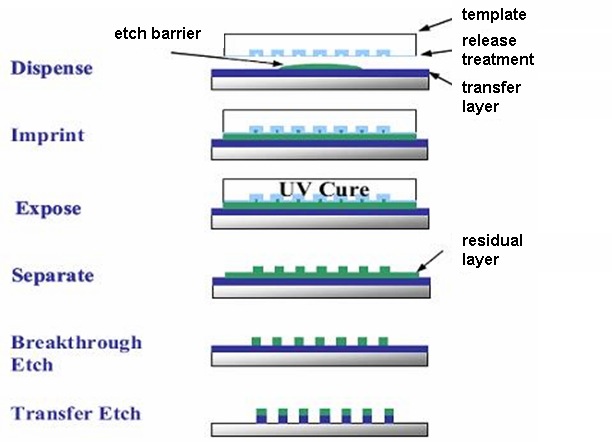

Step and Flash Imprint Lithography (SFIL) has demonstrated the ability to produce high resolution (sub 30nm) features. SFIL (see Fig. 1) is a low pressure molding process that uses a low-viscosity, UV-curable organosilicon solution to transfer the topography of a rigid UV-transparent template to the substrate. A surface treated, UV-transparent template is pressed against the dispensed liquid resist over a silicon substrate coated with an organic transfer layer. The capillary forces drive the liquid resist to fill the template features on a so-called mesa, a raised surface of an imprint template where active (pattern containing) area is located. The raised mesa ensures that only the patterned area of the template contacts the imprint fluid on the wafer surface while regions outside the mesa are held at a safe proximity away from the wafer. The resist is then cured by exposing UV light from the backside of the template. The template is finally removed leaving a low surface energy replica of template features on the coated substrate. This relief image is finally transferred through transfer layer as a high aspect ratio image into the substrate using oxygen RIE (reactive ion etching).

Although the imprint lithography greatly reduces the cost and complexity associated with optics in optical lithography, it has several engineering challenges. The SFIL imprint step is the most sensitive to defects among all the steps shown in Fig. 1. During the SFIL imprint step, the complete filling of template features is important to replicate the features on substrate. Incomplete or slow diffusion of a gas entrapped in the features; and improper

Figure 1: Steps involved in the SFIL Process: Liquid dispensing, imprinting, UV exposure, template release, etching.

Figure 2: (a) SEM image of 1000nm posts in resist (reverse replica of pores in template) after UV exposure showing non filling of pores during imprint step, (b) Cross sectional view of unfilled feature illustrating pinning of resist at feature edge.

replication of template features (as shown in Fig. 2) could potentially affect the throughput and the fidelity of the process. This advocates the need for a proper understanding and quantification of feature filling phenomena. Thus, this work is devoted to investigate the feature filling dynamics for SFIL, including: (i) the feature filling via diffusion of a gas entrapped in the feature through liquid imprint resist; and (ii) pinning of the air-liquid interface at the feature edges.

Continue reading >> Feature Filling