Biochip Research

Contact Information:

Saul LeeOverview

What are biochips? Biochips are devices that can contain anywhere from tens to tens of millions of individual sensor elements (or biosensors). The sensors are packed together into a package typically the size of a microscope slide. Because so many sensors can be put into such a small area, a huge number of distinct tests can be done very rapidly.

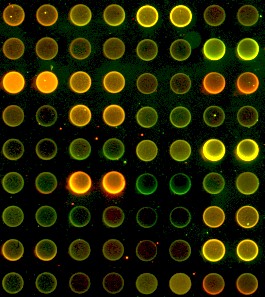

Biochips are often made using the same microfabrication technology used to make microchips. Unlike microchips, however, biochips are generally not electronic (although they can be). The key premise behind biochips is that they can do chemistry on a small scale. Each biosensor can be thought of as a "microreactor" which does chemistry designed to sense a specific analyte. Biosensors can be made to sense a wide variety of analytes, including DNA, protein, antibodies, and small biological molecules. Fluorescence is often used to indicate a sensing event. Automated microscopy systems can be used to "read" the chip, i.e. determine which sensors are fluorescing.

Research

Most biochips are 2D arrays of sensors placed carefully in a grid arrangement. The position of the sensor on the chip determines its function. For example, a sensor at the x-y coordinate (4,5) might sense the antibody for HIV, while the sensor at (7,3) might sense the antibody for an influenza virus. To place the sensors in precise coordinates, sophisticated and expensive microdeposition techniques are used. The sensors are essentially placed one at a time, or serially, on the chip. Thus, throughput and yield tend to be low.

We are developing a biochip that indexes sensor function to its shape, instead of its position on the chip. Thus, the sensors can be placed anywhere. Image recognition software can then then used to read the chip. The shaped sensors are made via a novel contact lithography. The benefits of this approach are multifold:

- The sensors can be batch produced and then assembled together in parallel, providing high throughput and high yield.

- The sensors can be packed very tightly together, unlike those deposited with microdeposition systems.

- The sensors are 3D in nature, and thus provide a higher signal than 2D sensors of other chips.

- Almost any chemistry can be incorporated into the sensors. Most biochips use only one type of chemistry.

- Because the sensors are produced offline and assembled later, they can be custom tailored for their specific application.