|

|

|

|

|

Process Flow

|

Photolithography Process Flow Please click on the

links below for more information on resist modeling techniques.

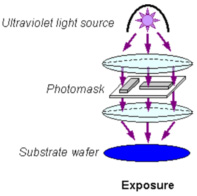

2. Exposure The second step is exposure of the film. During exposure, ultraviolet light passes through a photomask into the photoresist film. This ultraviolet radiation is absorbed by the film and causes a chemical reaction that alters the film composition in the exposed regions. In many classes of photoresists, exposure to ultraviolet radiation results in the generation of acid molecules within the film. These acid molecules will later catalyze a reaction that alters the solubility of the film in exposed regions.

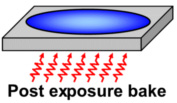

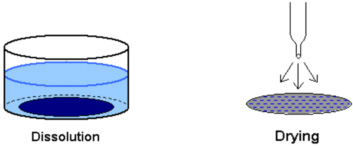

3. Post Exposure Bake  4. Development In the last step, the substrate is immersed in liquid developer. Many photoresists are based upon acidic polymers; these resists are developed in an aqueous base solution. In the exposed regions, the film is very soluble and is quickly removed. In the unexposed region, the dissolution rate is much lower and the film remains. The end result of the entire process is that the pattern from the photomask has been transferred into a three dimensional topography of photoresist.  Next: Film Creation Module |

|

|

Last

updated September 11, 2002 |

||