|

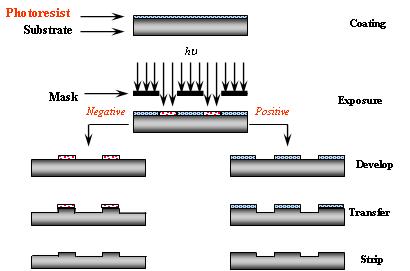

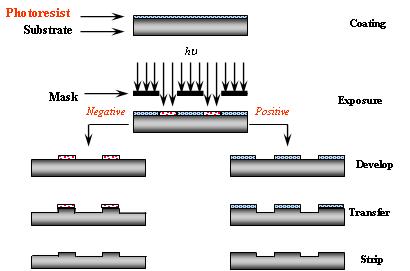

| Figure 1 |

Background |

| The resolution (R) of the lithographic process is defined by the Rayleigh

Equation, |

| where k1 is known as the Rayleigh coefficient,

l

is the vacuum wavelength of the exposing radiation, n is the index of

refraction of the ambient medium through which the exposing radiation is

focused,q

is the angular half aperture of the lens and NA stands for the numerical

aperture of the lens. [2] |

| Improvements in lithographic patterning have led to the continual

shrinking of device feature sizes and the resulting performance

improvements and cost reductions seen in today’s electronic devices.

These improvements have historically been achieved through the

development of new exposure sources with lower wavelengths.

Accompanying incremental improvements in the lens system by the

reduction of k1 and the increase of NA through larger q’s

have also contributed. |

| Early exposure tools used 436 nm light from the

g-line emission of a mercury arc lamp, followed by 365 nm light from its

i-line emission. Krypton-fluorine (KrF) excimer lasers then replaced

mercury arc lamps for leading edge lithography with 248 nm light, and

the state of the art is now argon-fluorine (ArF) lasers producing light

at 193 nm. |

|

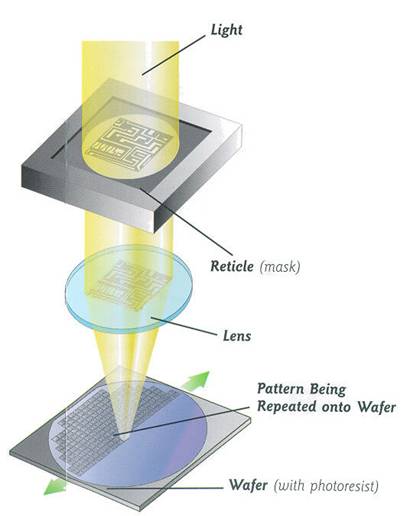

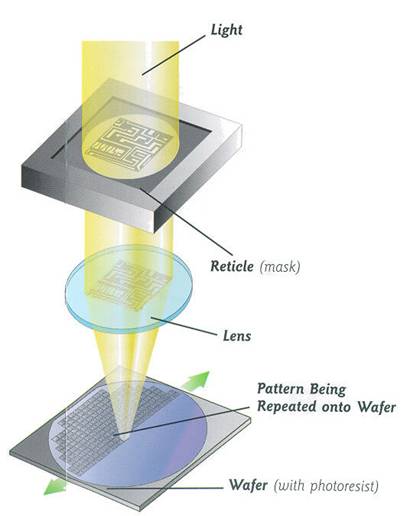

| Illustration of exposure through mask and focusing by lens.

|

| With each step down in wavelength, optical systems had to be redesigned and new

materials have had to be developed.[3] To move below 193 nm, the

development is complicated by the need for completely new materials for

the lens systems as well as the photoresist platforms and the necessity

for exposure to take place in vacuum. The rising costs of such

development has led to the resurrection of a novel lithographic process

first proposed in the 1980s called immersion lithography.[4][5][6][7]

Immersion lithography with the 193 nm exposure wavelength is now

considered the most likely candidate for printing features at 45nm and

below.[8] |

| Continue to Immersion Lithography Theory |

References |

| 1. Thompson, L.F.; Willson, C.G.; Bowden, M.J. Introduction to Microlithography.

American Chemical Society, Washington, DC. 1989.

|

| 2. M. Switkes, M. Rothschild, R. R. Kunz, S-Y. Baek, D. Cole, M. Yeung,

Microlithography World 12(2), 4, 2003.

|

| 3. Stewart, M.D.; Patterson, K.; Somervell, M.H.; Willson, C.G. J.

Phys. Org. Chem. 2000; 13: 767-774.

|

| 4. A. Takanashi et al., US Patent No. 4480910,

6 Nov. 1984

|

| 5. Lin, B. J. Microelectron. Eng.1987,

6, 31.

|

| 6. Kawata, J.; Carter, J. M.; Yen, A.; Smith, H. I. Microelectron.

Eng. 1989, 9, 31.

|

| 7. H. Kawata, I. Matsumura, H. Yoshida, K. Murata, Jpn. J. Appl.

Phys. 31, 4174, 1992.

|

| 8. International Technology Roadmap for Semiconductors: http://public.itrs.net/

|

Version History |

| Original page created 02/23/06 |

| | |