SFIL Multi Imprint Machine |

| A multi-imprint Step and Flash Lithography machine that can perform

repeated imprints on 200 mm wafers was developed for the purpose of

defect analysis, and is shown in Figure 1. This machine can imprint high

resolution (sub-100 nm) features from quartz templates using a

step-and-repeat process.

Multiple imprints are performed by moving an 8” wafer to various X-Y

positions while holding a template stationary. For the multi-imprint

process, it is necessary to have the compliant flexure affixed to the

template since a rigid template and compliant wafer stage can lead to an

unstable configuration for imprinting away from the center of the

substrate.1 The orientation stage design that can

tilt a template about the two “remote axes” that lie on the

template-wafer interface was developed and described

here. Two flexures are mounted orthogonal to each other

in order to generate two tilting motions, about the

a

and

b

axes. |

a) b)

b) |

| Figure 1: Multi

imprint apparatus construction. (a) Stripped-down Ultratech 1700 (II)

stepper, and (b) the completed SFIL stepper in its current form. |

| The major machine components include the following: (i) a

micro-resolution Z-stage that controls the average distance between the

template and the substrate and the imprinting force; (ii) an automated

X-Y stage for step and repeat positioning; (iii) a

pre-calibration stage that enables attainment of parallel alignment

between the template and substrate by compensating for orientation

errors introduced during template installation; (iv) a

fine-orientation flexure stage that provides a

highly accurate, automatic parallel alignment of the template and wafer

to the order of tens of nanometers across an inch; (v) a flexure-based wafer

calibration stage that orients the top of the wafer surface parallel

with respect to the plane of the XY-stage; (vi) an exposure source that

is used to cure the etch barrier; (vii) an automated fluid delivery

system that accurately dispenses known amounts of the liquid etch

barrier; and (viii) load cells that provide both imprinting and

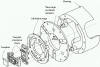

separation force data. An exploded view of the calibration stage

is shown in Figure 2. |

|

| Figure 2. Exploded view of calibration stage

assembly. |

| The multi-imprint apparatus is currently

configured to handle 1-in. square templates. It is used to produce more

than 20 imprints on 200 mm wafers for defect studies. The installation

of the template and the loading and unloading of the wafer are performed

manually. The printing operations, including X-Y positioning of the

wafer, dispensing of etch barrier liquid, Z-translation of the template

to close the gap between the template and wafer, UV curing of etch

barrier, and controlled separation are all automated. These unit

processes are controlled by a LabVIEW interface. |

| For a short movie showing the

Multi Imprint Machine in action, click HERE. |

| 1. Tan, H., A. Gilbertson, and S.Y. Chou. J. Vac. Sci. Tech. B,

16(6) (1998) 3926. |

b)

b)