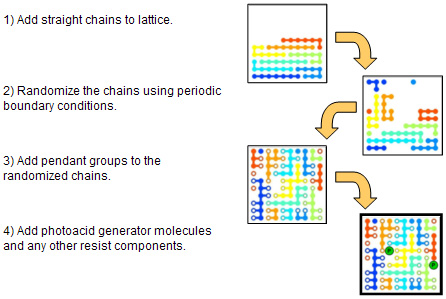

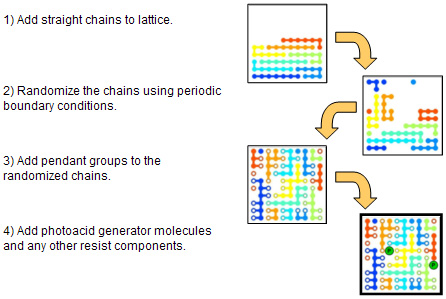

Film Creation |

The lattice model for a photoresist film is based upon fundamental and measurable

resist properties. To specify the polymer component, both the

average degree of polymerization and the standard deviation of the distribution of

degree of polymerization are input. It is also necessary to know the

average fraction of the polymer repeat units that are chemically

protected. Concentrations of other photoresist components, most notably

the PAG loading and presence of residual casting solvent, must also be

quantified. Knowledge of the chemical composition of the photoresist

enables calculation of the appropriate population of each component in the

lattice. Each component can then be added sequentially until the desired

concentration is present. In the first step of lattice creation, chains

are added to the lattice by stringing cells together to the desired chain

length and chain length distribution. These chains are then randomized via

many simulated reptation-type moves that have the effect of introducing

bends into the chains and eventually randomizing their conformation.

Periodic boundary conditions are employed so that the simulation is

effectively modeling an infinite plane of resist material. After

randomization, pendant groups are added to random positions on the chains

to represent blocked sites on the polymer chains. This approach produces a

normal distribution of blocking fractions for the chains. Photoresists

typically consist of random copolymers, so this distribution of blocking

fractions is an accurate representation of what would be found in an

actual resist. Finally, PAG molecules are included by adding PAG units to

random lattice vacancies until the required concentration of PAG has been

achieved. Other components, such as added base and residual casting

solvent, may be added in a similar manner.

|

Click here to download a movie that

illustrates how chains are added to an empty simulation lattice

(15.7MB).

|

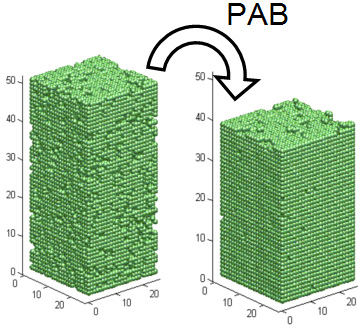

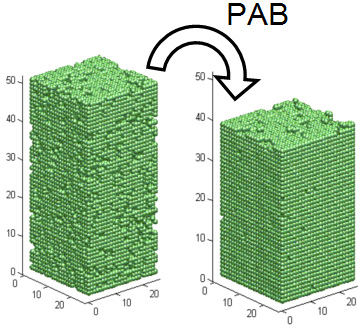

After creating the resist model in this manner, the lattice approximates

the configuration of the film after the spincoating step. It is then

necessary to simulate the post apply bake (PAB) step. During the PAB,

intermolecular interactions are important in the processes of solvent

evaporation and film shrinkage. A Monte Carlo simulation is performed that

allows the effects of specific intermolecular interactions to be

considered. (Details of this simulation have been published, and the

references are available on this website.)

|

Click here to download a movie

showing solvent evaporation and film shrinkage during the PAB simulation

(3.4MB).

|

|

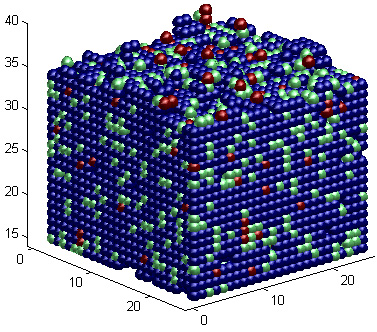

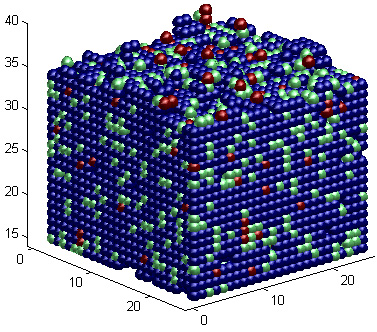

After the PAB simulation, the resist lattice model contains a realistic

configuration of polymer chains, photoactive molecules, solvent, free

volume, etc. This lattice model is the starting point for the next

simulation module, the exposure step. |

|

|

Next:

Exposure Module

|