Block Copolymer Nanolithography

Current optical photolithography technology approaches limits for achievable feature size. To continue fueling the momentum of the $200+ billion/year semiconductor industry, manufacturers are looking at new resolution enhancement strategies to overcome the physical photolithography limits.

Block copolymers (BCP) are a class of self-assembling materials that form features smaller than the 20 nm required for a next-generation technology. This makes them prime candidates for next-generation lithography.

Silicon-Containing Block Copolymers

Incorporation of silicon into the BCP allows for the creation of a robust etch mask, creating a material with inherent benefits. While a multitude of researchers have looked into using silicon-containing, cylinder-forming block copolymers for lithography, our group has uniquely developed materials and processes to use vertically-oriented lamellae-forming silicon BCPs for this application. This puts us in a unique position to decouple the orientation of a BCP from its lithographic performance.

Top-Coat Solution to Wetting Layer Problem

It is well known that silicon compounds, like silicon-containing BCPs, form wetting layers in thin films, making them useless for lithography. Our group, however, has developed materials to circumvent this problem and enabled silicon-containing BCPs to be used for lithography.

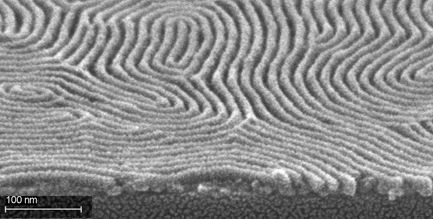

Orientation control is key to enabling BCPs for lithography. Here is an image of one of our silicon-containing materials. Observe the 8 nm features- essentially a world record for this application.

Applying a Top-Coat to a silicon-containing BCP can neutralize the air interface and create perpendicular features. Read about our Top-Coat solution, subscription free, here. PDF.

In addition we have since developed specific methodology for determining the chemistry of the "perfect" surface neutralizing material. Read about it here (2014).

Next Steps

This is still a very active research area in our group. Current thrusts include directing the block copolymer features to form circuit-relevant features. In addition, we are continually developing new block copolymer materials for better lithographic performance.