| MOSFET Device |

| SFIL was used to pattern the poly-Si gate in a MOSFET

device. Figure 1(a) shows a simplified industrial MOSFET process flow

for the fabrication of the transistor gate. In this process, the

starting substrate is a wafer in which the field oxide and the gate

oxide has been grown, the poly-Si deposited, and the oxide hard mask in

place, This would be spin-coated with resist, exposed, and developed

leaving the patterned resist features. These resist features would then

serve as an etch mask to pattern the hard mask and ultimately pattern

the underlying poly-Si for the transistor gate. The SFIL technique

replaces the spin-coating and exposing steps used in conventional

lithography with the process flow seen in Figure 1(b) and described

below. |

|

| Figure 1.

(a) Simplified industry MOSFET process flow for gate fabrication. (b)

Additional steps employed by SFIL. |

| The starting substrate was a Si wafer

that possessed gate oxide, isolating field oxide, and blanket poly-Si

and hardmask films. A layer of poly(hydroxystyrene) was spin-coated to

act as an adhesion layer for the imprint planarization step. Imprint

planarization was performed using 4% Darocur 1173 (Ciba) in ethylene

glycol diacrylate and imprinting with a blank template. The standard

SFIL process was performed on this substrate. |

| The alignment was performed on an

existing Canon 501 mask aligner at that has been modified for the SFIL

process. Using optical microscopy, this tool has the capability of

detecting alignment error,

making the corresponding corrections in X, Y, and theta, and performing

the UV exposure to complete the imprint. The process was performed

by first manually dispensing a small amount of etch barrier on the wafer

in the area to be imprinted. The wafer was then raised on a

hydraulic piston into close proximity of the template. As the etch

barrier filled the template relief patterns, a thin layer of fluid

prevents the wafer from actually making contact with template.

This thin fluid film, referred to as the residual layer, acts as both a

lubricant and a damping agent allowing adjustment in the alignment to be

made. With a small gap of ~0.25

m

m between the template and the wafer, both the alignment marks on the

wafer surface and the template are in focus through the backside of the

template and fine alignment could be performed with minimal optical

errors. |

| Alignment between the underlying poly-Si

and the SFIL patterned template was required to define the gate

structures over the active areas of the wafer. Rough alignment in the

theta direction was performed using a simple cross-in-box pattern. The

cross feature was previously defined on the wafer surface and the box

pattern was present in the relief image on the template. Fine alignment

was performed using Vernier marks in the X and Y directions. The

alignment resolution could be resolved from the resulting imprint by

determining which marks on the Vernier scale were aligned. With the

center marks aligned, the resulting overlay error was found to be less

than 0.25 mm. Following the iterative

process of alignment, the imprint area was irradiated with UV light,

polymerizing the etch barrier and leaving an organosilicon relief image

that is a replica of the template pattern, an example of which is shown

in Figure 2. |

|

| Figure 2. Example polymer gate structure. |

| The standard etch sequence was performed to etch through the residual layer,

transfer layer, hardmask, and poly-Si. The remaining fabrication steps

were completed using conventional processing techniques. Following gate

patterning, each wafer underwent implantation, isolation oxide growth,

contact patterning, and aluminum deposition. An example of one of the

completed devices used in these experiments is shown in Figure 3 . These

devices did not undergo an anti-punch-through implant, source/drain

extensions, or silicide gate cap due to time constraints on the

project. These steps are within our processing capability and will be

included in future device fabrication processes. |

|

| Figure 3. Completed MOSFET device. |

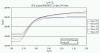

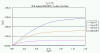

| Following processing, the completed devices were electrically tested. Both drain

current vs. drain voltage (Id vs. Vd) and drain

current vs. gate voltage (Id vs. Vg) curves were

obtained and can be seen in Figure 4. These I-V curves confirm the

functionality of the fabricated MOSFET devices and the successful

incorporation of SFIL in creating a working electrical device. The

electrical data are also consistent with other electrical devices

fabricated with conventional lithographic techniques using similar

processing equipment |

a) b)

b) |

| Figure 4. (a) Ig vs. Vg

curves for sintered PMOSFET, Ltarget = 2

mm, W =

23 mm.

(b) Id vs. Vd curves for sintered PMOSFET, Ltarget

= 2 mm,

W = 23 mm. |

|

|

© 2006 Willson Research Group, University of Texas at Austin

Last updated

Site design by Arrion Smith and Obi

SFIL Content by Todd Bailey

|

![]()