| |

|

|

|

|

|

|

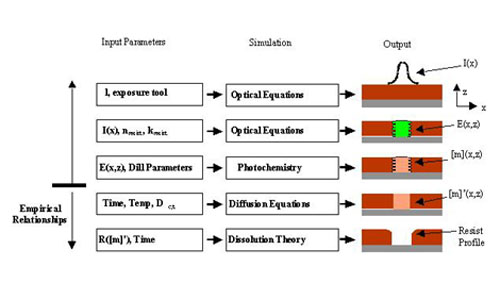

Resist

Modeling Process

|

|

|

|

| Photoresist modeling

and simulation requires knowledge of the exposure and

dissolution properties of a resist and the

characteristics of the exposure tool. The sequence

steps in the simulation are shown in Figure 6.

Exposure modeling involves the calculation of the

laser image intensity as a function of position (I(x)).

The propagation of that intensity function into the

photoresist is described by Beer's law and requires

knowledge of the real and complex index of refraction

(n and k) of the resist and substrate. An increment of

dose is applied at the film surface. The energy

deposited (# of photons) in any volume element E(x,z)

is then calculated from the knowledge of the resist

and substrate n, k. The energy is allowed to react

with the PAC to convert a proportion of it to a

photoproduct and to create a local relative PAC

concentration in the film, m(x,z). This process is

continued until a prescribed exposure dose is

accumulated. The interference of light due to

reflections at the resist-substrate interface creates

an oscillation in the exposure energy and thus creates

an oscillation in the PAC concentration. The PAC is

then "diffused" by a baking process to

create a final PAC concentration distribution m'(x,y,z).

Knowledge of the dissolution rate as a function of PAC

concentration (R(m)) then allows the simulation to

remove volume elements at the appropriate rate to

simulate the dissolution and thereby generate a resist

profile. |

|

|

|

|

|

|

|

|

|

Last

updated Monday, February 14, 2000

© 2000 Photomask Lithography, Willson Research

Group,

University of Texas at Austin

Phone: 512.471.6364

Email:

rathsack@mail.utexas.edu

Site design by Arrion Smith

|

|

|

|

|

|

|

|

|

|

|

|