| Ring-Opening Metathesis Polymerization (ROMP) of

Functionalized Dinorbornene Monomers for 157 nm Lithography Applications |

| Ring-Opening Metathesis Polymerization |

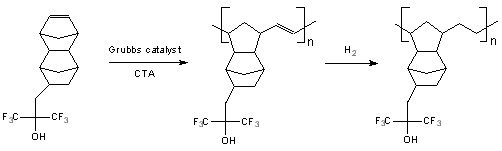

| ROMP is once again being investigated as a viable polymerization pathway for 157 nm

lithography. In conjunction with Daniel Sanders of

CalTech, ROMP using the Grubbs catalyst and optimal chain transfer agents (CTA) to control polymer

molecular weight. Monomers to be used will be functionalized dinorbornenes in order to increase

the glass transition temperature of the resultant polymers. Primary concern centers on what

trade-off will be paid in optical density with the addition of another norbornene ring. |

| ROMP and 193 nm Lithography |

|

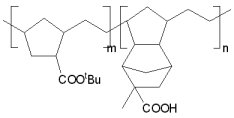

| ROMP was previously explored in the Willson group for use in 193 nm lithography, using an

iridium-based catalyst (K2IrCl6). Monomers used were based on norbornenes, with dinorbornenes

used at times as well. During the project, glass transition temperatures were able to be

increased above 130 ºC. However, problems where encountered when trying to image the ROMP

polymers, such as swelling and incompatabilities with some PAGs. |

| ROMP and 157 nm Lithography |

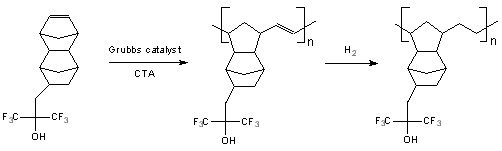

| Now ROMP is being investigated yet again for use at 157 nm, this time using functionalized

dinorbornene monomers to for the first set of polymers. The Grubbs catalyst, a ruthenium-based

catalyst, is being used in lieu of the iridium catalysts. The homopolymer of the dinorbornene

hexafluorocarbinol monomer, which shows that the Grubbs catalyst is tolerant of the highly polar

and acidic hexafluorocarbinol group. |

|

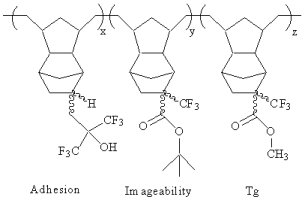

| Preliminary data shows that the consequence of incorporating a second ring into the monomer

unit is not as high as intuition might suggest. Using Variable Angle Scattering Ellipsometry

(VASE), the homopolymer of the dinorbornene hexafluorocarbinol, cast from cyclohexanone, shows

a thin film absorbance of approximately 3.2/um. These results give reason to further pursue the

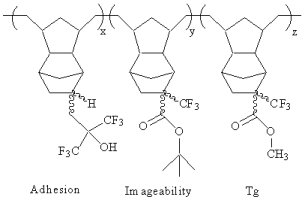

ROMP polymers and see if different substituents can yield all the functional modules required for

a polymeric resist material. |

|

| Future Work |

- Boosting methyl ester content of the polymer to raise the hydrogenated polymerYs Tg

- Copolymerizing with non-functionalized dinorbornene

- Copolymerizing with a variety of functionalized dinorbornene monomers

- Finding optimal chain transfer agents for molecular weight control

|

|

| References |

- T. Otsuki, K. Goto, Z. Komiya, J. Polym. Sci. A., 2000, 38, 4661.

- C.W. Bielawski, R.H. Grubbs, Angew. Chem. Int. Ed., 2000, 39, 2903.

- M. Scholll, S. Ding, C.W. Lee, R.H. Grubbs, Org. Lett., 1999, 1, 953.

- A.K. Chatterjee, J.P. Morgan, M. Scholl, R.H. Grubbs, JACS, 2000, 122, 3783.

- A.K. Chatterjee, R.H. Grubbs, Org. Lett., 1999, 1, 1751.

|

| Version History |

| Original page created 05/21/01 |