|

|

||

|

Development of 157 Photoresist Materials The purpose of this document is to provide timely public access to the 157 nm resist development work being done in our laboratories under contract from International SEMATECH. It is our goal and SEMATECH's goal to disseminate this information as rapidly and widely as possible in hope that doing so will accelerate the availability of 157 nm resist materials to the members of International SEMATECH. Protecting Group Module To gain an understanding of the appropriate methods for acetal protection of hexafluoroisopropanol moieties, a series of model studies was carried out using compound I. One common method of acetal formation involves treatment of an alcohol with a vinyl ether and a catalytic amount of acid (1). Unfortunately, the use of HCl or other acids as the catalyst for this reaction was completely unsuccessful at preparing the desired acetal. A catalyst reported to aid in the formation of acetals from tertiary alcohols, triphenylphosphine hydrobromide (2), was also found to be ineffective in this case. It is possible that a different catalyst might be capable of mediating this reaction, but we decided to pursue other methods.

Fortunately, there are other pathways for the preparation of acetals, including the reaction of an alcohol with a chloromethyl ether in the presence of a base. The treatment of compound I with a strong base such as n-butyllithium or sodium hydride followed by addition of chloromethyl ethyl ether gave the desired acetal in encouraging yields.

Functional test of hexafluoroisopropanol / acetal combination Although a successful method was found to readily protect hexafluoroisopropanol functionalities with acetals, it was not clear whether this combination would be an effective combination in a photoresist. Previous examples of hexafluoroisopropanols in photoresists consistently utilized tert-butyl carbonates for the protecting group, and therefore give no indication of what to expect with acetal protecting groups. As a result, the best method available to test the functional compatibility of these two moieties is to prepare a model photoresist polymer and evaluate the resulting lithographic ability. In order to change as few variables as possible, an existing polymer architecture developed for 193 nm photoresists and offering well-described lithographic behavior was modified to incorporate an acetal-protected hexafluoroisopropanol group.

Synthesis of norbornene monomer Synthesis of this copolymer involves the preparation of the hexafluoroisopropanol-functionalized norbornene, reported by Ito (3). The preparation of this molecule is a two-step procedure beginning with formation of an allyl hexafluoroisopropanol imtermediate, through Grignard reaction between allyl magnesium bromide and hexafluoroacetone (4). The second step involves a Diels-Alder reaction between this intermediate and cyclopentadiene under elevated heat and pressure. Following the synthesis of the norbornene monomer and acetal protection of the hydroxyl group with chloromethyl ethyl ether as outlined for the model compound, the alternating copolymer with maleic anhydride was prepared using the same procedure outlined for our 193 nm photoresist materials (5).

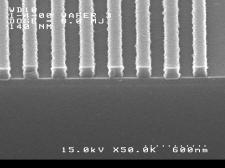

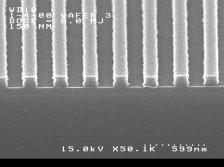

A photoresist formulation was prepared from the final copolymer

for lithographic evaluation at an exposure wavelength of 193 nm. As this study was intended only to

verify the compatibility of hexafluoroisopropanol acid groups with acetal

protecting groups, the ultimate resolution capability of this system was

unimportant. Instead, focus was placed on screening the imaging results for phenomena such as undissolved

residue between the patterns (known commonly as scumming) or an unusually high

imaging dose that would indicate an incompatibility between these two functional

groups. Imaging results are shown below. The

features shown are (left) 140 nm and (right) 150 nm linewidths,

1:1 pitch. The processing conditions were as follows: Film thickness = 125

nm. PAB and PEB = 120ºC / 60s. imaging dose = 8 mJ /cm2, develop 0.26N

TMAH, 30s.

FTIR spectra were also taken at various doses prior to development to measure the amount of deprotection.

The figure below shows the normalized concentrations of both the acetal

functional groups (1165-1192 cm-1) and deprotected hydroxyl groups

(3100-3572 cm-1). The experiment was repeated a second time, and both sets of results are shown.

The results from the imaging test are extremely encouraging,

indicating that the deprotection reaction proceeds as expected by FTIR, and no

signs of unfavorable interactions between the acid group and protecting group

are indicated.

1) Green, T. W., Wuts, P. G. M. “Protective Groups in Organic Synthesis”, John Wiley and Sons,

New York, 1991.

2) Bolitt, V., Mioskowski, C., Shin, D.-S., Falck, J. R. Tetrahedron Letters

1988, 29, 4583.

3) Ito, H., Reichmanis, E., Nalamasu, O., Ueno, T., eds. “Micro- and Nanopatterning

Polymers” American Chemical Society, Washington D.C., 1998, pg 208-223.

4) Okamoto, Y., Yeh, T. F., Lee, H. S., Skotheim, T. A. J. Polym. Sci. Part A: Polym.

Chem. 1993, 31, 2573.

5)Patterson, K., Okoroanyanwu, U., Shimokawa, T., Cho, S., Byers, J. D., Willson, C., G.

Proc. Soc. Photo-Opt. Instrum. Eng. 1998, 3333, 425.

| |

|

|

||